Polpharma SA,

Pharmaceutical plant

in Starogard Gdanski

Pharmaceutical plant

in Starogard Gdanski

One of the largest, state-of-the-art pharmaceutical factories in Europe – here, we manufacture medicines such as Pyralgina, Polopiryna, Ranigast, Etopiryna and Scorbolamid.

LVP

DPE Large Volumes Parenteral (BFS)

Hard capsules

SVP

LDPE Small Volumes Parenteral (BFS)

Solutions and emulsions in glass ampoules

Tablets

Main competencies:

solid dosage forms, parenteral forms SVP/LVP

New competencies:

ophthalmic forms, pfs, LVP/SVP in Polipropylen

Plant annual production

capacity

capacity

4billion

tablets, capsules per year

140million

ampoules (solutions for injection in glass ampoules, solutions for infusion in PE, liquids for external use) per year

510 megaton

active pharmaceutical

substances per year

substances per year

The Polpharma Pharmaceutical Plant in Starogard Gdanski is primarily a Drug Production Plant and the only API Plant in Poland that produces large-scale active pharmaceutical substances. The company was originally founded at this site in 1935 as the Polish Chemical and Pharmaceutical Factory, “Polpharma”, after which the plant was significantly damaged during World War II. In the years 1945–1949, factories were nationalised and rebuilt.

In 1951, the enterprise changed to Starogardzkie Zakłady Farmaceutyczne.

The company was restored to its former name “Polpharma” on 1 December, 1995, and was privatised on 20 July 2000, with the participation of the Polish capital.

In 1951, the enterprise changed to Starogardzkie Zakłady Farmaceutyczne.

The company was restored to its former name “Polpharma” on 1 December, 1995, and was privatised on 20 July 2000, with the participation of the Polish capital.

Drug production plant

There are 575 specialists employed in the Drug Production Plant and 1500 products are manufactured here. The plant is constantly expanding, particularly in the areas of glass ampoules, polypropylene infusion fluids and dry mould production capacity.API plant

Polpharma is the largest Polish producer of active pharmaceutical substances (API).Our substances are available in over 60 countries on 6 continents.

Location

- Starogard Gdanski (airport 47 km, Warsaw 320 km)

- Total area 24 ha

Certification

- EU GMP certificatee

- Russian GMP certificate

- US FDF – API plant

Solid dosage forms production department Starogard Gdanski – tablets & hard capsules

Production started in 2001 and is located on 6 floors.

The building is designed for a vertical flow of material. Processes are supported and controlled by the MES system. Parameters of the environment in production rooms are controlled by the BMS system

Special manufacturing conditions possibility:

Special manufacturing conditions possibility:

- Decreased humidity and temperature

- Area organic solvents (EX zone for solution preparation)

- Photosensitive products (production in yellow light)

Equipment:

- 12 tablet presses (Korsch; FETTE)

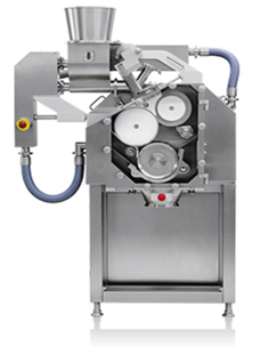

- 2 capsulation machines (IMA; MG2)

- 1 compactor (Alexanderwert)

- 4 granulation lines (GLATT; GEA)

- 6 coaters (GLATT)

-

13 packaging lines:

11 blisters lines (Bosch; IMA; Marchesini)

1 stripes lines (Siebler),

1 plastic bottles line (King; Marchesini)

Main processes:

- Weighting

- Sieving

- Granulation: dry mixing, wet granulation, FB

- Mixing

- Tableting, encapsulation: 2-3 layers tablets, effervescent tablets

- Packaging: blisters, strips, plastic bottles

Capacity for tablets,

capsules is 4 billion

per year

capsules is 4 billion

per year

Parenteral forms

production department

Starogard Gdanski

production department

Starogard Gdanski

Glass ampoules:

-

Solutions for injection

in glass ampoules

(2ml, 5ml, 10ml, 20ml)

Parenteral fluids in PE:

- LDPE Large Volume Parenteral (LVP) from 60mL, 100 mL, 200 mL 300mL, 500mL

- LDPE Small Volume Parenteral (SVP) from 5mL, 10mL, 20mL

- Single-dose eye drops 0.5 ml in sets of 12 pcs

Production in Glass Production Section started in 2005.

The building was designed in compliance with the latest requirements of cGMP.

The building was designed in compliance with the latest requirements of cGMP.

Due to the extension of the sterile forms production facility, free capacity for sterile forms can be offered from mid-2021.

Weighting and solution preparation are is automated and controlled by MES. The process is automated for all production steps: washing, depyrogenation, filling, optical inspection, and leak detection.

Parameters of the environment in production rooms are controlled by BMS and PMS.

Two methods of glass ampoules production:

Parameters of the environment in production rooms are controlled by BMS and PMS.

Two methods of glass ampoules production:

- Aseptic filling

- Terminal sterilization

Process parameters are online controlled and fully documented. Possibility to manufacture a wide range of ampoule formats from 2 ml to 20 ml.

Parenteral forms production department Starogard Gdanski – parenteral fluids in PE

Production is out based on Blow-Fill-Seal technology.

A container is formed, filled and sealed in a continuous process without human intervention, in a sterile enclosed area inside the machine. The area is equipped with various BFS machines. Aseptic filling based on sterile filtration through 0.2 µm membranes Thermal sterilization in an autoclave (108°C).

Equipment:

- 8 solution preparation lines (KATES)

- 3 autoclaves (Getinge)

- BFS machines: 1 Asep Tech (Weiler), 6 Bottle-Packs (Rommelag)

- 2 packaging equipment (CARIBA BIPAK) 6 labelling machines (Unilogo, Helf, Intrex, Marchesini)

Capacity for liquid

form is 120 million

per year

form is 120 million

per year